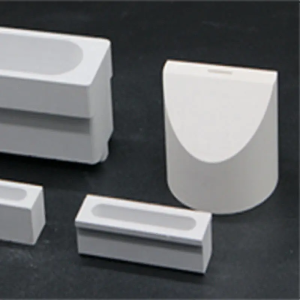

Introducing Itowu Ceramic Materials – Advantages, Characteristics, and Applications

As the demand for high-quality materials continues to increase, ceramic materials have become a popular choice among many industries. Among these high-quality materials is Itowu, a type of ceramic material that offers unique advantages and properties that make it ideal for various applications.

Advantages of Using Itowu Ceramic Materials

One of the main advantages of Itowu ceramic materials is their exceptional strength and durability. These materials are highly resistant to wear and tear, making them ideal for use in applications where materials are subjected to harsh conditions or heavy use.

Another advantage of Itowu ceramic materials is their excellent thermal and electrical conductivity properties. These materials can withstand high temperatures and are suitable for use in applications that require heat resistance or electrical insulation.

Applications and Industries that Use Itowu Materials

Itowu ceramic materials are used in a wide range of industries, including aerospace, automotive, electronics, and healthcare. These materials are commonly used in applications such as turbine blades, engine components, medical implants, and electrical insulators.

In the aerospace industry, Itowu materials are used in the production of aircraft engines and parts, while in the automotive industry, they are used in the manufacturing of engine components and brake systems. In the electronics industry, Itowu materials are used in the production of electrical insulators and other high-performance electronic components.

Conclusion

Itowu ceramic materials offer a range of unique advantages and properties that make them ideal for various high-performance applications. Their strength, durability, and resistance to wear and tear make them an excellent choice for industries that require high-quality materials. Whether in the aerospace, automotive, electronics, or healthcare industry, Itowu materials continue to be a popular choice among many manufacturers and engineers.